In house rubber track pad installation on Bobcat T320 with Steel Undercarriage.

Wednesday, January 30, 2013

Rubber Track Pads for T300-T320 Bobcats With Steel Tracks

Prowler MFG's product line now includes rubber track pads for the Bobcat T300 and T320 Compact Track Loaders with steel tracks. Because these machines have an entirely different undercarriage they cannot be swapped from steel to rubber or vise versa. Prowler offer rubber track pads for these machine so the the customer can use their steel tracked compact track loader in more job site conditions then ever. WE have supplied several Bobcat dealers these track pads to put on these machines as an option that actually helped them make the sale. Many customers are interested in steel tracks for compact track loaders but decide against the purchase of these machines because the machine cannot be swapped back and forth. Now you can have a CTL with steel tracks or one with rubber.

In house rubber track pad installation on Bobcat T320 with Steel Undercarriage.

In house rubber track pad installation on Bobcat T320 with Steel Undercarriage.

Thursday, January 24, 2013

Prowler Guard Dog Skid Steer Tires

Prowler's American Made Skid Steer Tires are proving to be the best in class. Reasonably priced and OEM quality this is the Premier choice tire for skid steer owners. These tire are being reordered by customers saying the quality is the best they have seen and the durability is top notch. Customers are repeating the tire orders for their quality and good pricing. Many of our customers are taking advantage of our wheel and tire combinations where the customer can save big money and time. When you receive a skid steer wheel and tire combo from prowler your tire will be mounted and ready to install on your wheeled skid loader, saving you time of going to a local tire shop and having the old tires taken off and the new ones mounted.

Monday, January 21, 2013

Prowler Skid Steer Tires and Wheels

Friday, January 18, 2013

8 easy ways to make your compact construction equipment last longer.

Downtime is the enemy, regular

maintenance does not cost you money, it saves you money! These 8 tips

can solve a high percentage of compact construction equipment

problems.

- Service your machine regularly, preferably according to manufacturer’s guidelines. If you do not want to follow those guidelines, at least have some sort of “working hour” based maintenance plan in place.

- NEVER let your machinery run out of fuel! Almost all modern diesel injector pumps rely on the fuel for lubrication. Running out of fuel even 1 time can ruin your injector pump and cost thousands of dollars of damage and headache.

- Check your final drive and swing motor cases monthly, and final drives daily if you are operating in water. Almost every final drive failure we see is caused by either no oil in the case or water in the case. Water must be drained out immediately if it finds its way into your finals.

- NEVER EVER let your machine run out of hydraulic fluid. If you have a hydraulic leak, fix it immediately. If you absolutely have to finish a job despite a leak, keep your fluid within normal operating range. Modern piston style pumps need the hydraulic fluid for lubrication. These pumps can often outlast the useful life of the machine unless contaminated. One gulp of air will cause irreparable damage to these pumps. If one of these pumps fails it can contaminate the hydraulic system with metal to the point of ruining the entire hydraulic system.

- Always use the correct hydraulic fluid. A large percentage of hydraulic “problems” we see are cause by people using the wrong type of fluid (ie using hyd “oil” rather than hydrostatic “fluid”)

- Check air intake for wear/damage regularly. Modern diesel engines are built to very tight tolerances and cannot handle any contaminates whatsoever. A small hole in an intake hose or a misaligned air filter can ruin an engine in a few hours of use in dusty conditions.

- Keep an eye on Rubber Tracks and Undercarriage. Most premature rubber track failures are caused by an undercarriage problem. If you buy and install new rubber tracks and do not address the problem that caused the track you are replacing to fail, the new tracks are going to fail prematurely. Key items to look for are sprockets, rollers, and idlers worn beyond normal tolerances. Be keen to the wear on your compact track loader sprockets. CTL sprockets do not wear in the same manner as a dozer or excavator. Sprockets of compact track loaders do not get sharp like that of an excavator or dozer. If your sprocket has ¼” of an inch of wear or more, the pitch will be off and not properly line up with the steel cross bars of the new tracks. When this occurs the drive torque applied to the track is forced on to a single cross bar instead of 2 or more (depending of the design of the undercarriage). Unless you have a premature track failure your sprockets normally need replaced by the time you are due to install new rubber tracks.

- Have basic spare parts you need on hand. You should always have at least one complete set of filters and enough of each fluid in your machine for complete replacement. If your machine holds 22 gallons of hydraulic oil, you should keep 22 gallons at your shop. The same applies for antifreeze, engine oil etc. Keep at least one bottom roller for tracked machines and one spare wheel and tire for wheeled machines. If affordable, keep a spare set of rubber tracks and sprockets on hand if you are not within driving distance of your supplier. It is far easier to install rubber tracks in your shop then in the mud at the job site. Do not wait until your rubber tracks are broken to order spares!

Tuesday, January 15, 2013

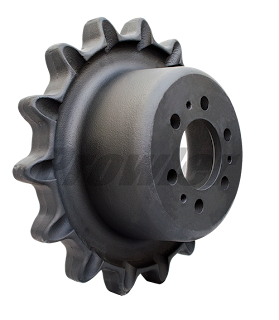

Compact Track Loader Undercarriage Parts

Prowler Rubber Tracks is proud to announce our new line of undercarriage parts. These new aftermarket replacement undercarriage parts for Compact Track Loaders (CTL) and Mini Excavators are OEM equivalent quality. Replacement Undercarriage parts such as Front Idlers, Rear Idlers, Track Rollers, and Sprockets. These new parts available for many makes and models of Excavator and Tracked Skid Steers such as:

Compact Track Loader:

Many Other parts available for many other models such as: Terex, Gehl, Mustang, Doosan, Volvo, Yanmar, Airmann and more. visit - www.prowlertracks.com or call 877-477-6953 for more info.

Compact Track Loader:

- Bobcat - T180, T190, T200, T250, T300

- Case - 420CT, 440CT, 450CT,

- John Deere CT322, CT332, CT315, CT323, CT333

- ASV - RC50, RC60, RC85, RCV, RC100, PT50, PT60, PT70. PT100

- CAT (Caterpillar) -267, 277, 287, 297, 279, 289, 299

- New Holland - C175, C180, C190,

- Takeuchi - TL130, TL140, TL150, TL230, TL240, TL250

Mini Excavators:

- Bobcat - 325, 331, 334, 337, 341

- John Deere- 27, 35, 50, 27zts, 35zts, 50ztc, 27c, 35c, 50c, 50d, 60d

- CAT - 302.5, 303, 303c, 304.5, 304ccr, 305ccr

- Komatsu - PC27, PC30, PC35, PC40, PC45, PC50, PC75, PC120, PC128

Friday, January 11, 2013

Rubber Tracks for Komatsu Dozers

Prowler Manufacturing is the exclusive source of replacement rubber tracks for Komatsu D20 and D21 Compact Utility Dozers. Heavy Duty Rubber Tracks are also available for Mitsubishi Bd2 , Bd2G and Furukawa FD40 and FD45. These Heavy Duty Continuous Rubber Tracks are available In standard 300mm 12" and 500mm 20" Low ground pressure styles (LGP). These tracks are not adapted mini excavator tracks, these are Direct OEM compatible deep treaded heavy duty tracks. Visit prowlertracks.com for more information or Call 877-477-6953. Alternatively you can Purchase these tracks direct from rubbertrack.com

Wednesday, January 2, 2013

Prowler MFG Skid Steer Attachments

Prowler MFG has one of the largest inventories of Heavy Duty Skid Steer Attachments. Skid Steer Pallet Forks, Grapple Buckets, Snow pushers, Tree Shears, and more. Visit - http://www.prowlertracks.com/prowler-skid-loader-attachments-for-sale.html

Subscribe to:

Comments (Atom)